| Ford Model A |

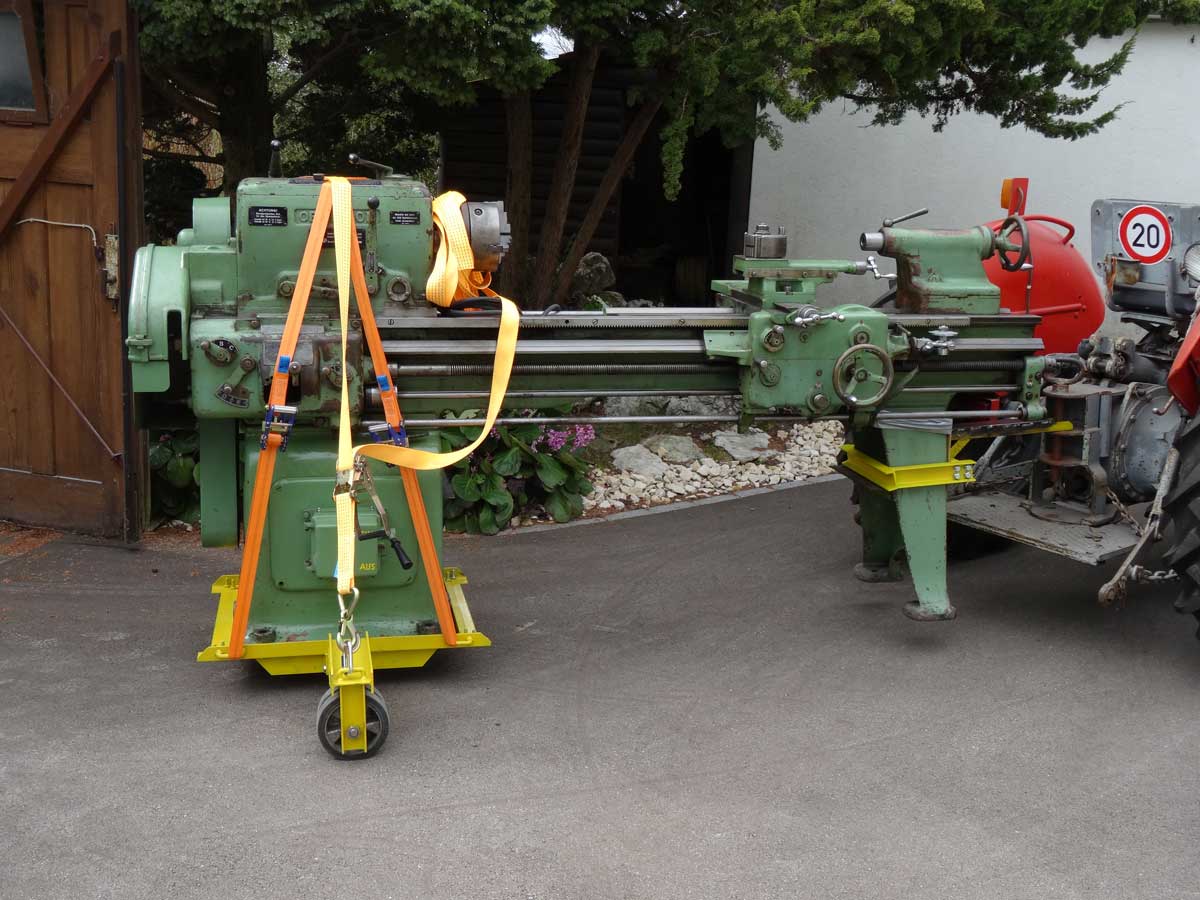

1.5 tons Lathe transport with self-made transport frame and tractor

Last month I already presented my welded transport cart for my old Oerlikon lathe. Now it was time to test this trolley, if it works and if it can carry the load of 1.5 to 1.7 tons.

In the meantime I painted everything yellow.

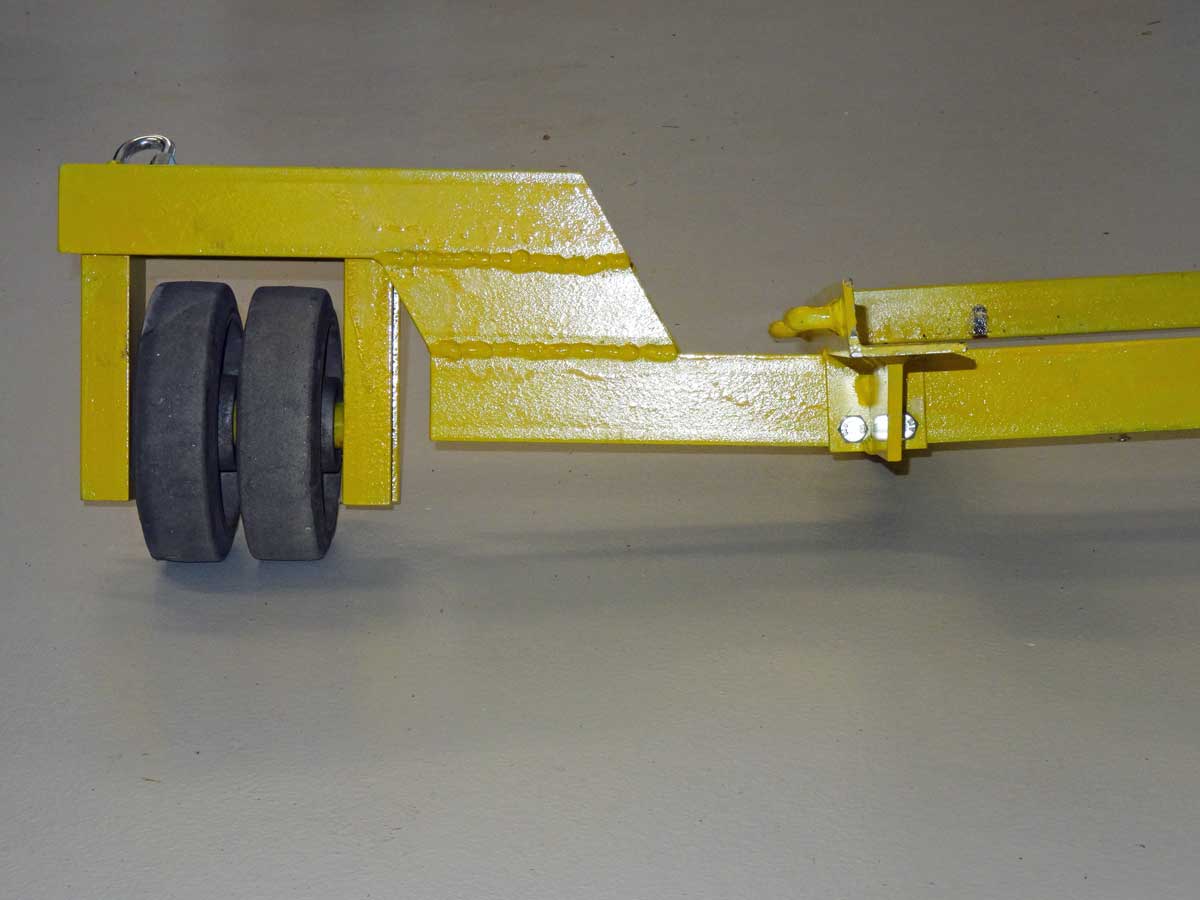

The trolley and the drawbar are ready and we can start.

Generally speaking, you have to know what you are doing and work carefully - if you don't, the lathe will be lying on its side faster than you think ;-) It is important to move the weight of the tailstock and tool slide to the right when lifting on the left side in front of the headstock, so that the leg on the right side has a stable stand and remains on the ground. The jack must then be used to lift the lathe at its center of gravity so that it does not tip forward or backward. In addition, I lift it a maximum of 1 cm and immediately underlay it with wooden blocks so that the lathe is secured against tipping.

On the chassis, I disassembled the angle profile on one side, then moved the trolley under the lathe base and was able to reassemble it. So far everything fits.

I also mounted the drawbar and then lifted it at the outer end for test ticks. The U-profile bent a bit more than expected and I decided to reinforce the drawbar.

For this I welded a flat steel on it and with that the drawbar holds the load without any problems.

To fix the lathe to the trolley, I have fixed the trolley and the lathe with 3 straps.

Now I can get the tractor and attach the lathe.

On the side of the drawbar I have enough space not to graze in curves or when maneuvering.

The short trip went without major problems.

The last meters are done by hand, i.e. with pallet truck and pallet on the side of the drawbar. This allows the foot to turn on the pallet and I can easily maneuver the heavy lathe with the pallet truck.

Now I can lift the lathe and remove the chassis.

The headstock side is on wooden beams and I can move the lathe closer to the wall.

I put hard rubber plates under the base and the yellow sheet metal flanged at the edges is my oil catch pan. At the old location, it always had oil on the bottom, and it's not exactly clear if the headstock is not completely tight. Better safe than sorry and for that reason I made this sheet metal to catch any oil that might leak out in it.

The lathe is now up, but it is not running yet.

I still have to change the old plug and I have a 50% chance that the motor will turn in the right direction. I unfortunately got the wrong 50% on the first try so I had to swap 2 more wires.

But before I can turn the three-jaw chuck, I have to check the oil level and oil pressure. When the motor is running, oil must be sprayed from the inside to the sight glass in all 3 speed levels (see drop in the middle of the sight glass). With me it had still too little oil and therefore I have refilled some hydraulic oil. After the warm-up and sufficient oil pressure, I then engaged the clutch and let the three-jaw chuck turn slowly so that the bearing would not be damaged after the long standing time of 4 years.

Now I still have to clean the entire lathe and remove various flash rust and then everything will be freshly oiled. With that, my lathe will soon be ready to turn the first parts again.

The transport of my lathe went positively, although a small thing happend, which I already saw as a risk before the transport, but did nothing about. One side of the double T-profile buckled by 1 cm (see picture), because at this point the biggest forces are acting and I also weakened the whole thing with 2 screw holes. I have already recognized the problem before the transport, but did not want to weld something more at the expense of ground clearance. Due to a stupid driving maneuver on my part, the full load was on this one side for a short time and therefore it came to this deformation, but the trolley still held and served its purpose :-)