| Ford Model A |

Self-made 2x72" / 50x2000 mm Tilting Belt Grinder - Mobile table with drawers

All chapters on the construction of my 2x72" / 50x2000 mm Tilting Belt Grinder:

Chapter 1: Description and performance features of the tilting belt grinder

Chapter 2: Deviations from Jer Schmidt's plans - Using Sanding belts 2x72" AND 50x2000 mm

Chapter 3: Steel cutting and welding

Chapter 4: Operating panel for motor control

Chapter 5: Spark collector, Spark arrester, Dust collector

Chapter 6: Mobile table with drawers for belt grinder

To be able to work comfortably with the belt grinder, I still need a work table with the right height. As this needs to be lower than normal workshop tables, I decided to build one myself.

The optimum working height is, when I can easily grip my work-piece with my forearms bent. For my height, this is approx. 104 cm. My table has a height of 68 cm plus the 3 cm for my wide foot, making a total of 71 cm from the floor. The 72" belt grinder is now placed at this height and the table of the belt grinder is then +/- 104 cm. These are all values that work for me. That's why I recommend everyone to take these heights as a starting height and see how relaxed you can work with them. Depending on this, you can then vary the height slightly up or down until it suits you personally.

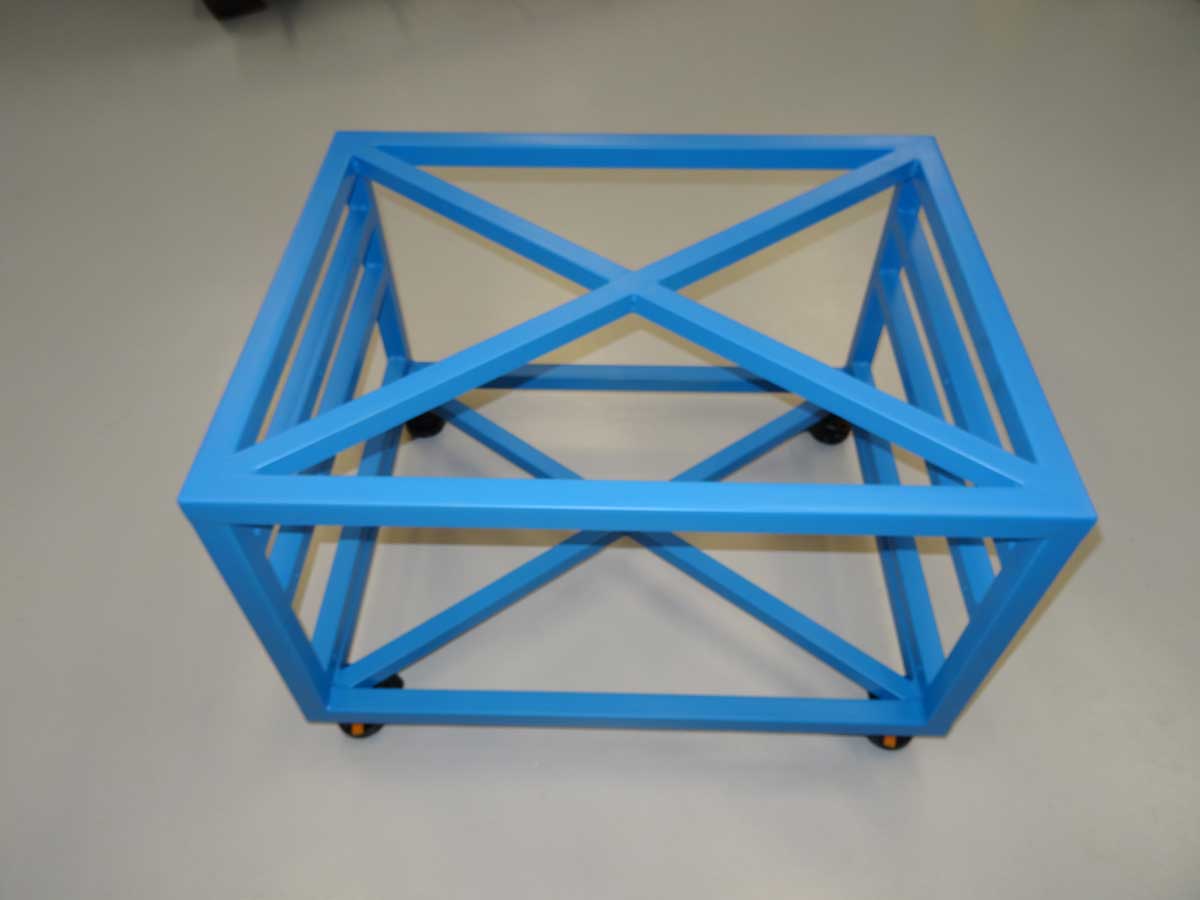

As already mentioned, my table is 104 cm from the floor plus the 3 cm for the wiede foot mentioned above. The construction is an open frame, i.e. you can see the 3 drawers directly.

This (solid) table also required some square steel tubes.

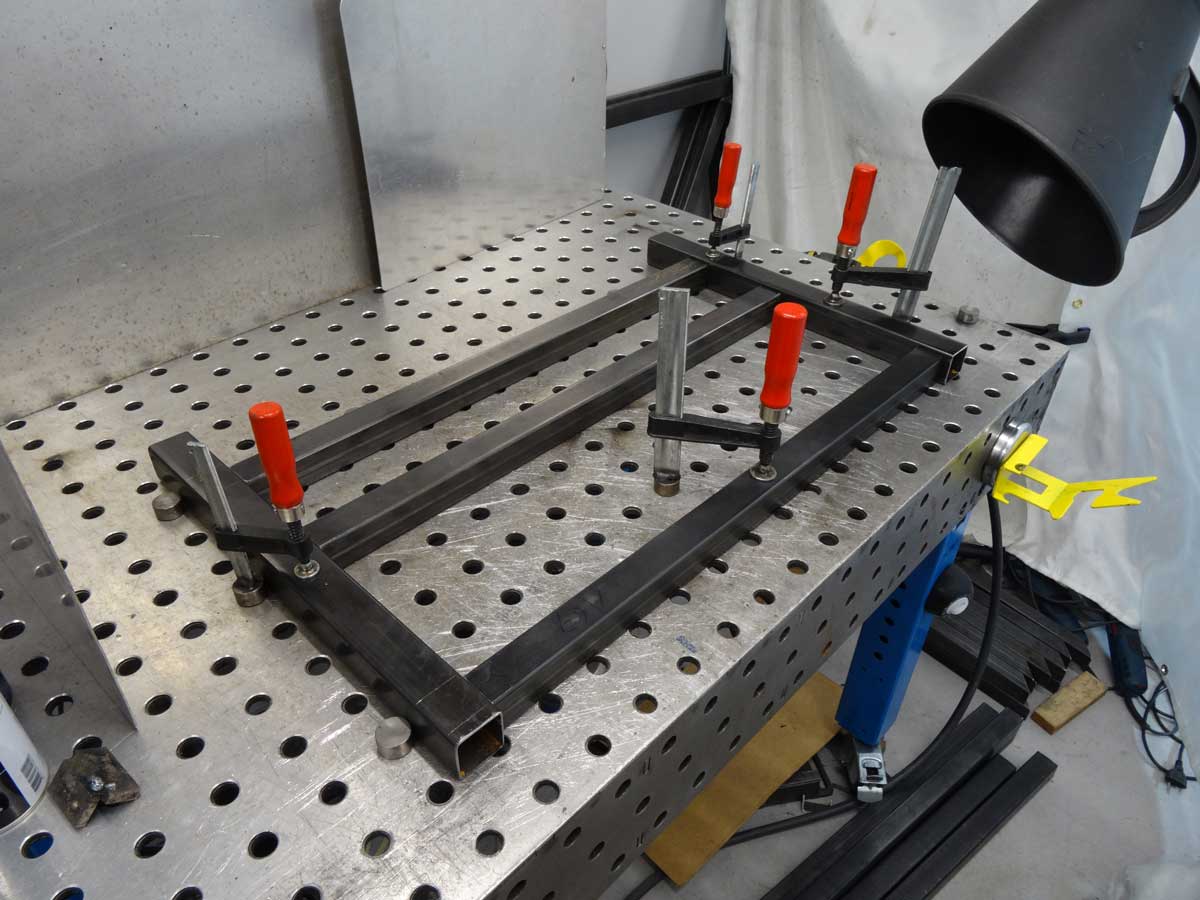

I then clamped the square tubes to the welding table and welded them together. You can't go wrong, because the right angles are guaranteed by the bolts in the welding table.

The edges are 40 x 40 mm square steel, the rest is 35 x 35 mm. In retrospect, I could certainly have used slightly thinner steel tubes.

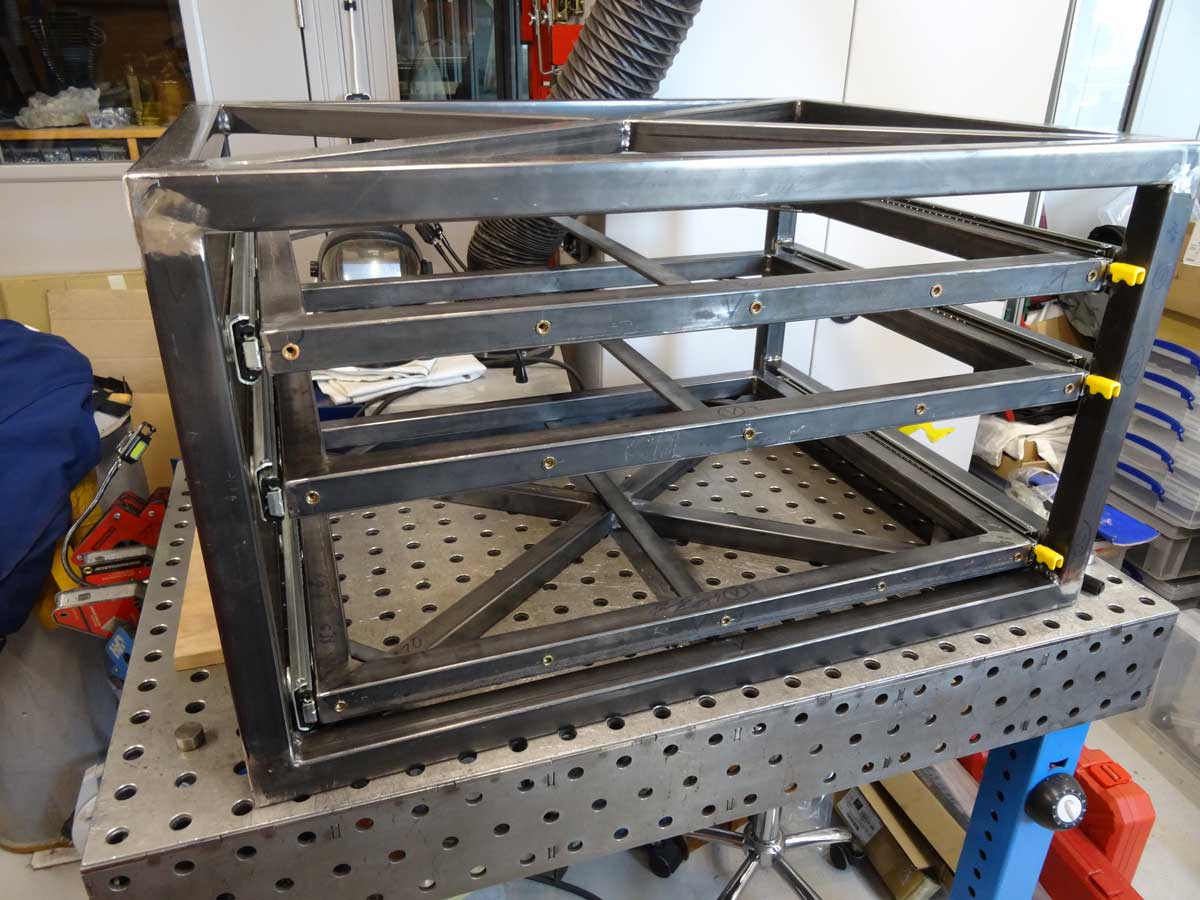

The 3 drawers are also fully welded.

Once all the rivet nuts have been fitted, I can assemble the drawer frames and rails for test purposes. The rails are 3-part and 100% extendable. They are locked in the closed and extended positions.

So far everything fits, it is important that the width of the drawers is correct, otherwise the balls of the rails will jam.

Now comes the woodwork with 18 mm beech wood. The front boards and those at the back are screwed to the drawer frame. The side boards have no connection to the frame, but are only screwed to the front board and the one on the back. The bottom consists of a board which is only inserted and not screwed.

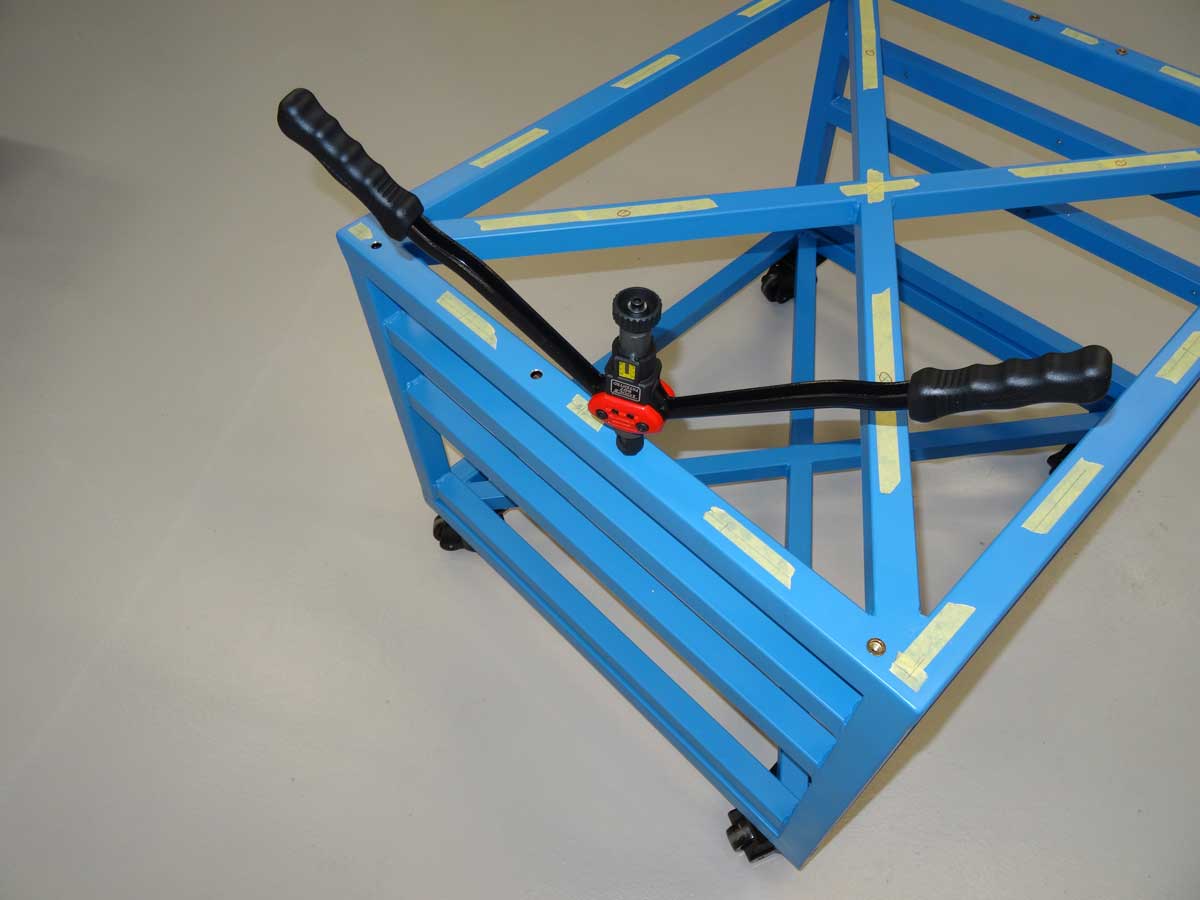

I use this version as castors, where I can extend a rubber foot with the help of the yellow ratchet to fix the table in place.

The frame is already standing on its own two feet.

I use 2 of these 1 m x 40 cm oak tops with a thickness of 4 cm.

After marking the holes, the rivet nuts are set.

The table is now fully assembled. Before assembly, I treated all the wooden parts with linseed oil varnish.

This is the view from behind.

The purpose of the strips screwed onto the side (above the drawer runner) is to protect the drawer runners from dirt.

That was the last chapter of my 72" belt grinder. Now have fun rebuilding Jer's 72" Tilting Belt Grinders (Gen 2 Design). To me it is the most well thought out version of a 72" belt grinder I have found on Youtube and I have watched dozens of them. And finally many thanks to Jer for his super plans!

Back to

Chapter 1 .