| Ford Model A |

Repairs / modifications to steel band saw

My band saw for sawing steel profiles is getting old and has various quirks, so that sawing is no longer fun. On the one hand I can hardly clamp the profiles anymore, because one hole is worn out and the cuts are also not in the right angle anymore, which does not make the later welding work easier.

This is my band saw.

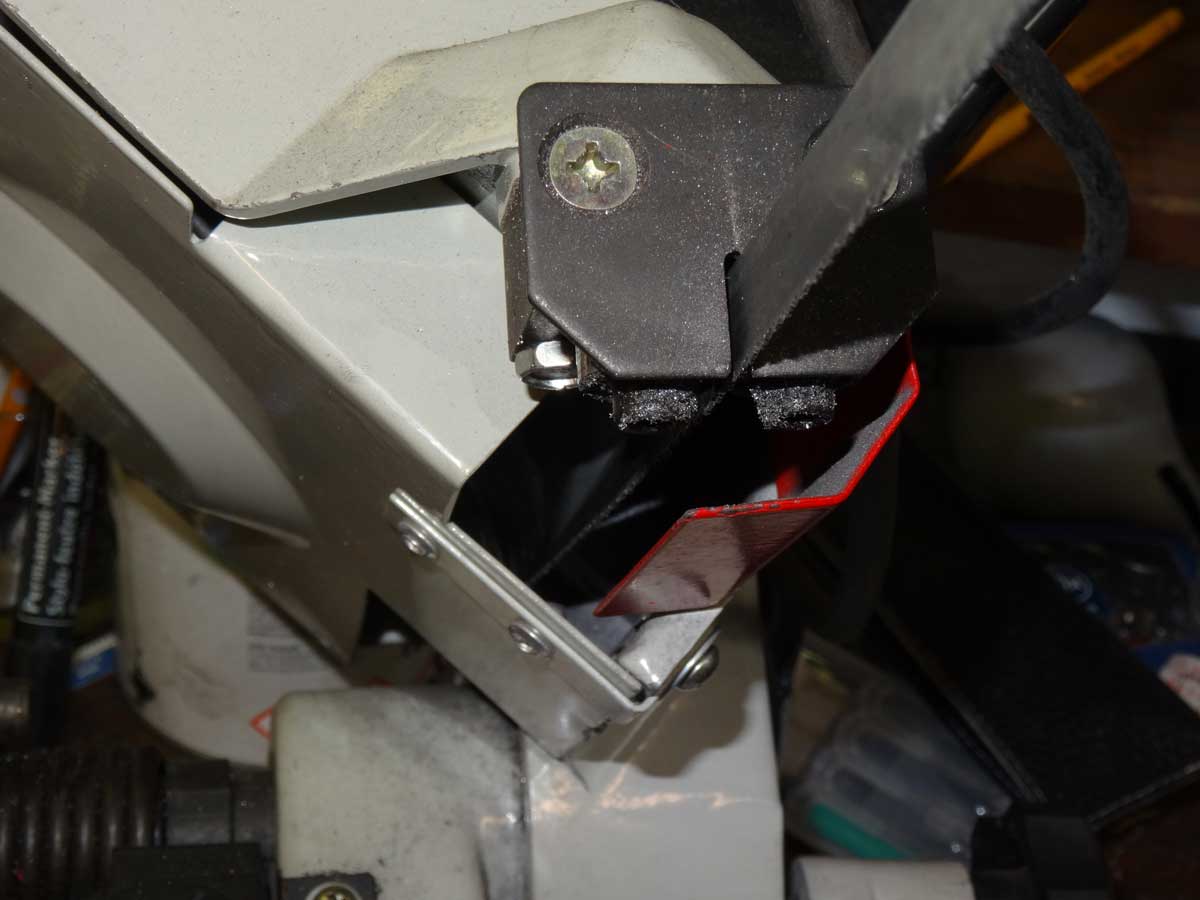

The saw band is guided on both sides by 4 ball bearings each.

As you can see in the background, the band is slightly twisted because the drive rollers are tilted 45 degrees. I suspect that the ball bearing guides have run out a bit and the saw band is no longer pressed 100% into the vertical position. There is nothing to readjust and so I had to come up with another solution.

I mounted a steel plate adjustable in the height at the vice on the outside, in order to be able to lift the steel profile which will be sawed.

Now I just had to make a few test cuts to find the right height.

For short pieces, I put a narrow 4 mm thick rectangular profile underneath and I also get a clean 90 degree angle that way.

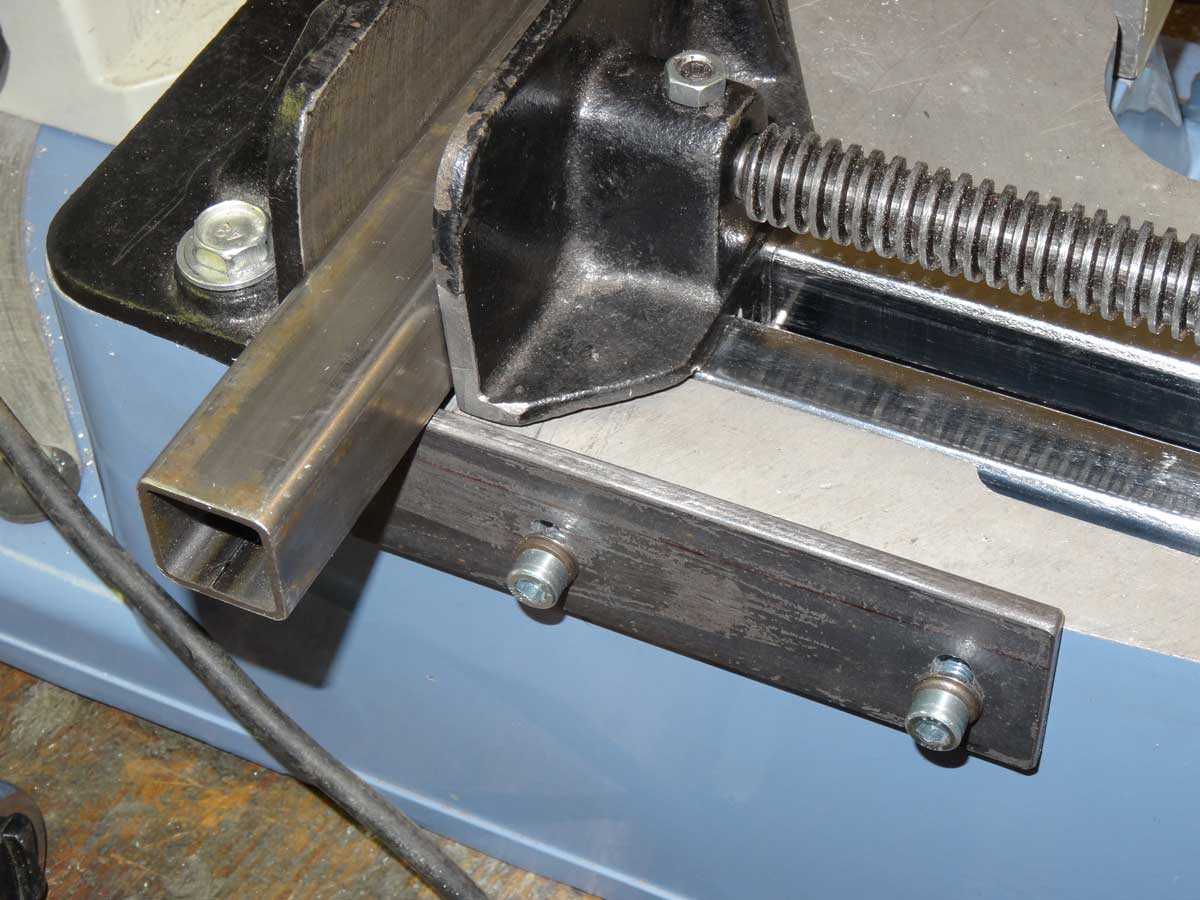

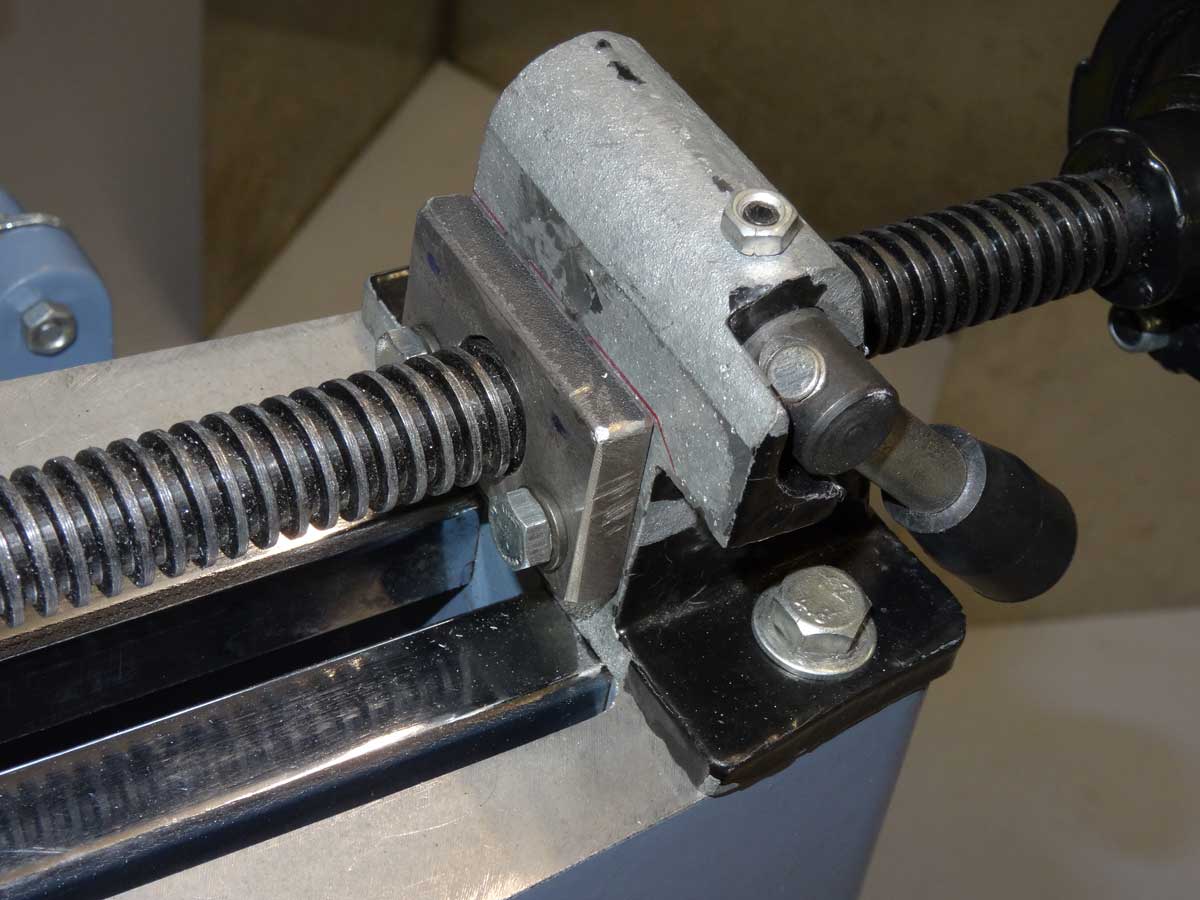

The bigger problem was with the vise, where the eccentric nut popped out of the thread when I clamped it tight and I always had the risk of a piece coming loose and then damaging the saw band. The reason for this behavior was a knocked out hole in the casting and as a result the threaded rod was too low and the eccentric nut (removed in the foreground on the picture) could no longer fully engage in the threaded rod. The solution is a thick flat profile, in which I drilled a suitable hole for the threaded rod and fixed it with 2 screws to the casting. The hole is now back at the original height and the threaded rod and nut can engage cleanly.

Here everything is mounted together. With the lever I can lift the nut and move the threaded rod back and forth. When the lever is down, the nut engages the threaded rod and I can clamp the parts in the vise using the rotary wheel.