| Ford Model A |

Ford Model A Pickup Restoration - Powder Coating all Fittings (September 2013)

During the past month I have completed most of the fittings of the wooden flatbed.

After removing the protective film, I shortly stopped with breathing when I saw the surface of this bar. In this case it was only the grinding dust which passed through a hole. I could wipe it away with some Water - me lucky …

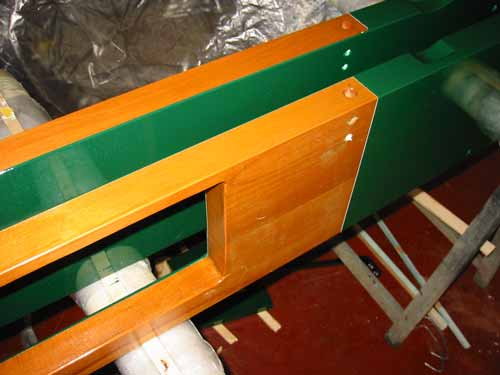

The visible parts on the outside are green, inside of the trunk it is visible. It took a ittle bit more time but it would be a shame not to show the nice wood.

The grate of the vent holes are painted in green so it fits to the rest of the car.

The protection profile for this board can be mounted too.

The wood is painted and glazed.

But now everything is stacked first. Before I can start assembling, I have to prepare some fittings, bolts and nuts first.

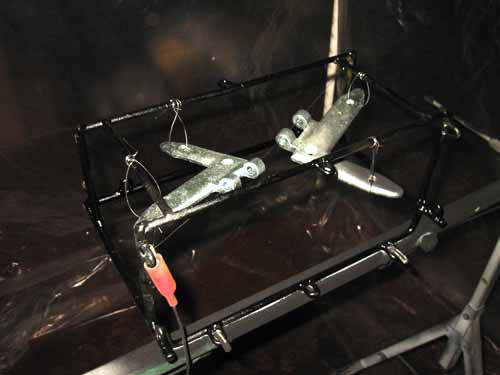

The fittings have been galvanized after sandblasting, what follows now is a black powder coating. Powder coating is the best for this type of hardware and I must not fear that the paint would chip.

The parts are coated with the powder and must now be heated up by 400 F.

Half of all parts are finished. Castings like these costs a lot of time, bcause they have to be preheated first. This must be done that all remaining gas comes out of the casting. Otherwise you will get lots of blisters all over the part.

Here you can see when the powder smooth and slowly begins to shine and becomes liquid.

I have locked one moving part with a wire. It is easier to fix the fittings that way.

And this is the second part of my hardware.