/ford_a/2024_11_e_eigenbau_bandschleifer_funkenschutz_funkenfaenger.en.html

All chapters on the construction of my 2x72" / 50x2000 mm Tilting Belt Grinder:

Chapter 1: Description and performance features of the tilting belt grinder

Chapter 2: Deviations from Jer Schmidt's plans - Using Sanding belts 2x72" AND 50x2000 mm

Chapter 3: Steel cutting and welding

Chapter 4: Operating panel for motor control

Chapter 5: Spark collector, Spark arrester, Dust collector

Chapter 6: Mobile table with drawers for belt grinder

Good spark protection is important to me, but not always easy to achieve, especially when the belt grinder is so flexible, as in this case.

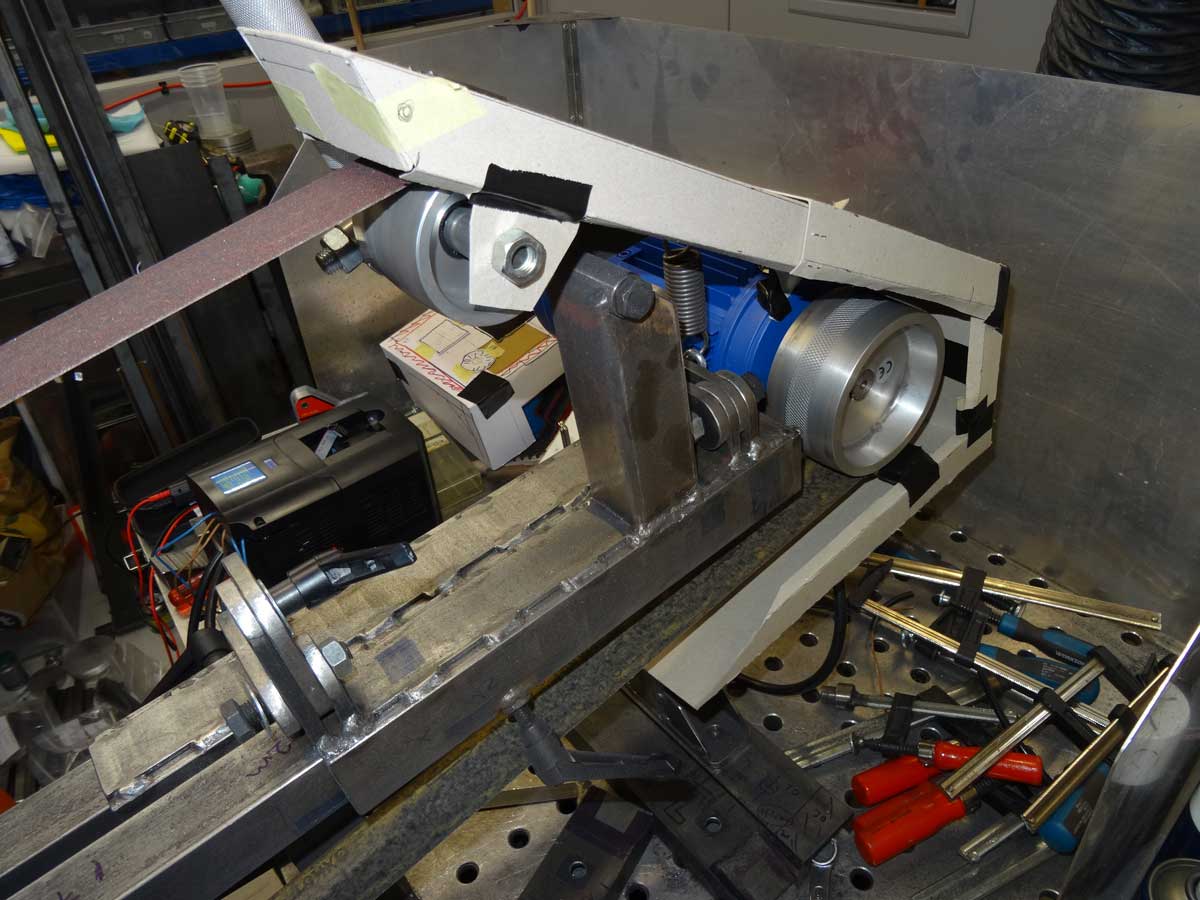

I opted for a combination of a permanently installed spark collector in the area of the drive and a flexible solution placed under the grinding table.

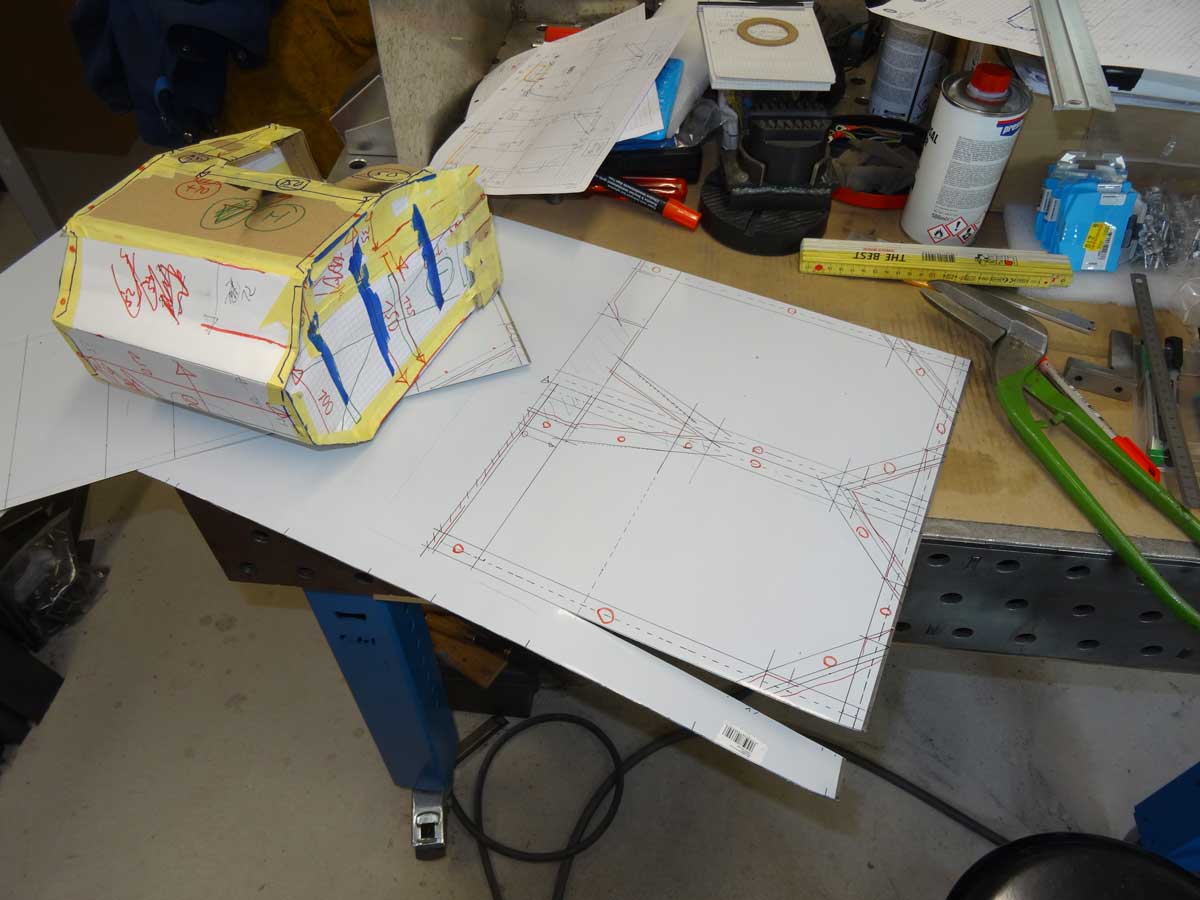

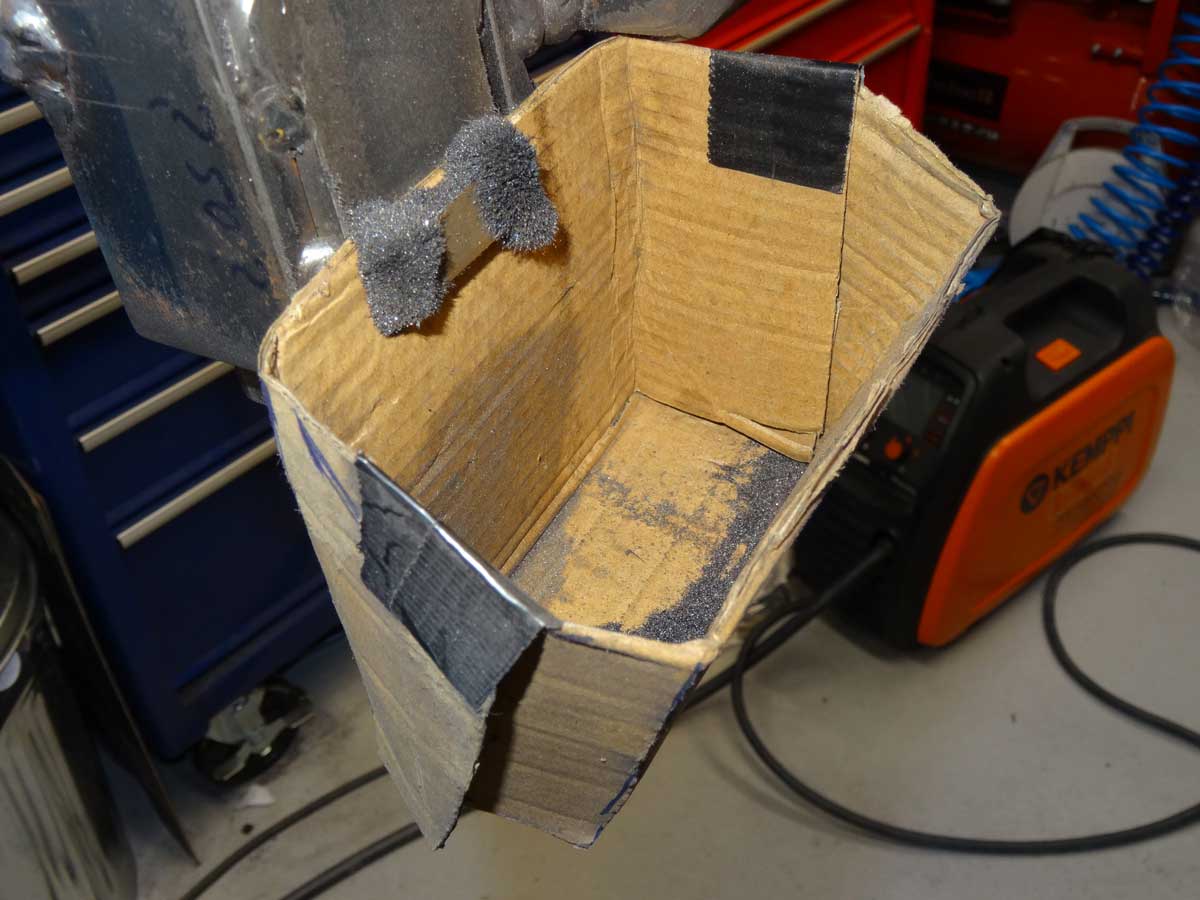

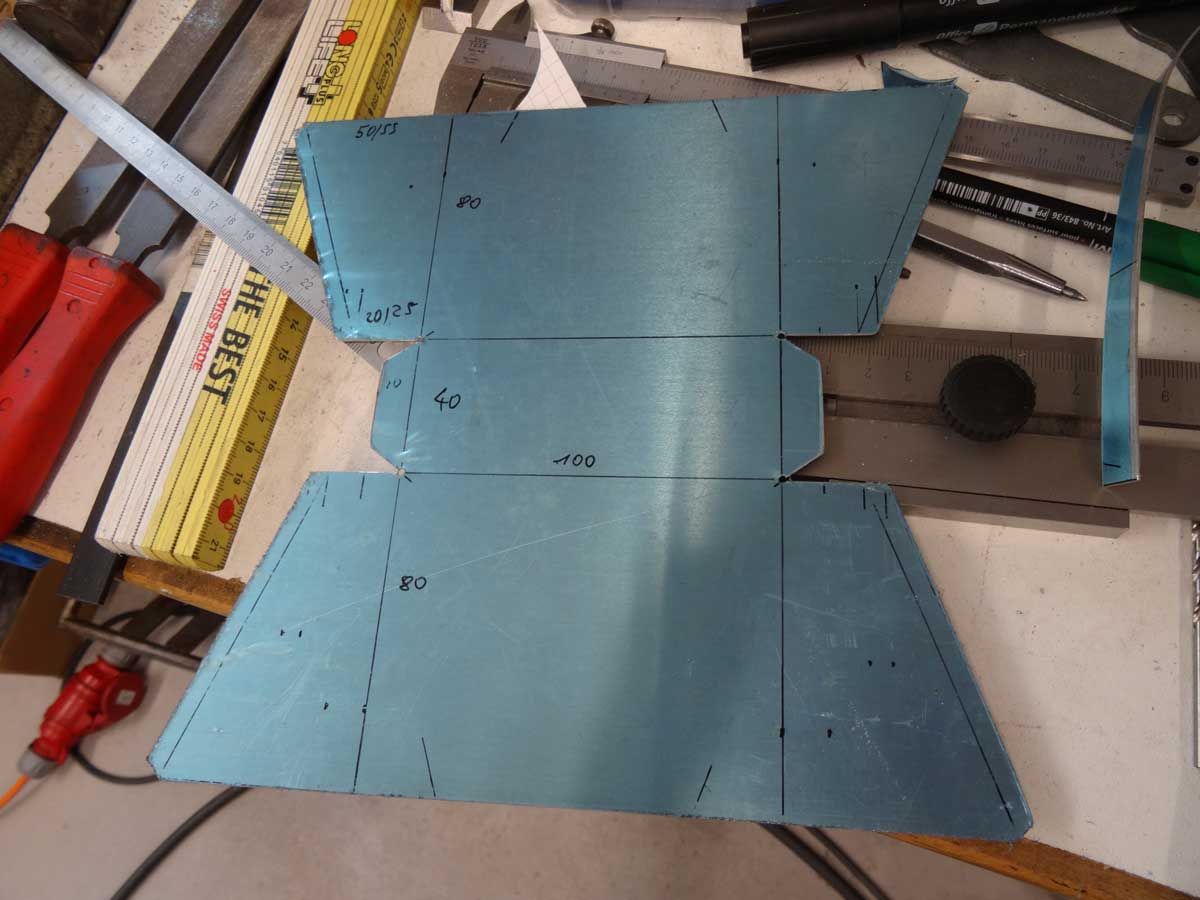

I created various cardboard models, modified them, cut off parts and glued them back on until I found the right shape. In this case, the cardboard model helped me a lot. As I don't have a program for simulating flying sparks ;-) I was able to use the cardboard model to test whether the sparks were being captured and to make improvements where necessary.

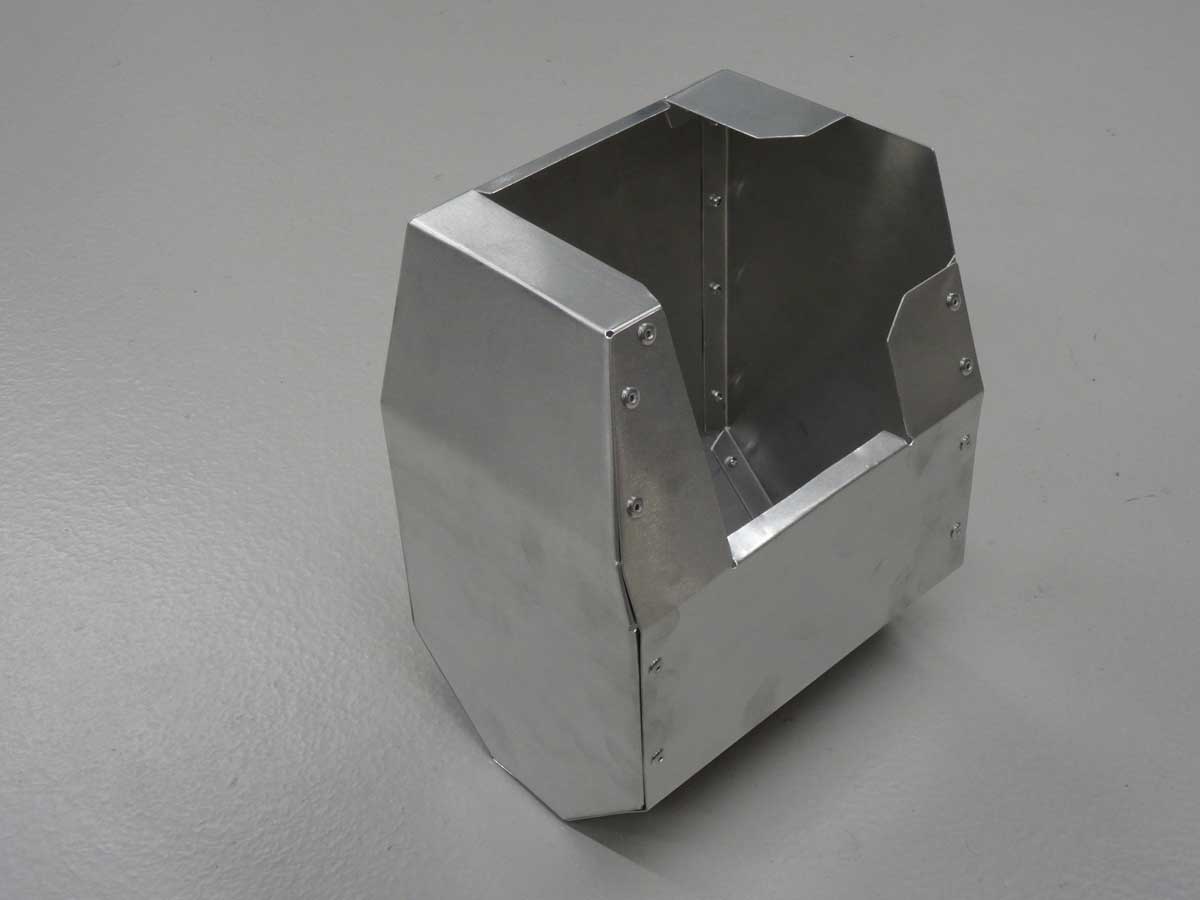

The spark collector in the operator area is in two parts and consists of flat steel for the frame and the 0.8 mm aluminum sheet screwed to it. A 0.8 mm thick aluminum sheet is ideal for this spark collector. With this sheet thickness, it is light and easy to work with (bend) and yet the bending gives it the stability it needs.

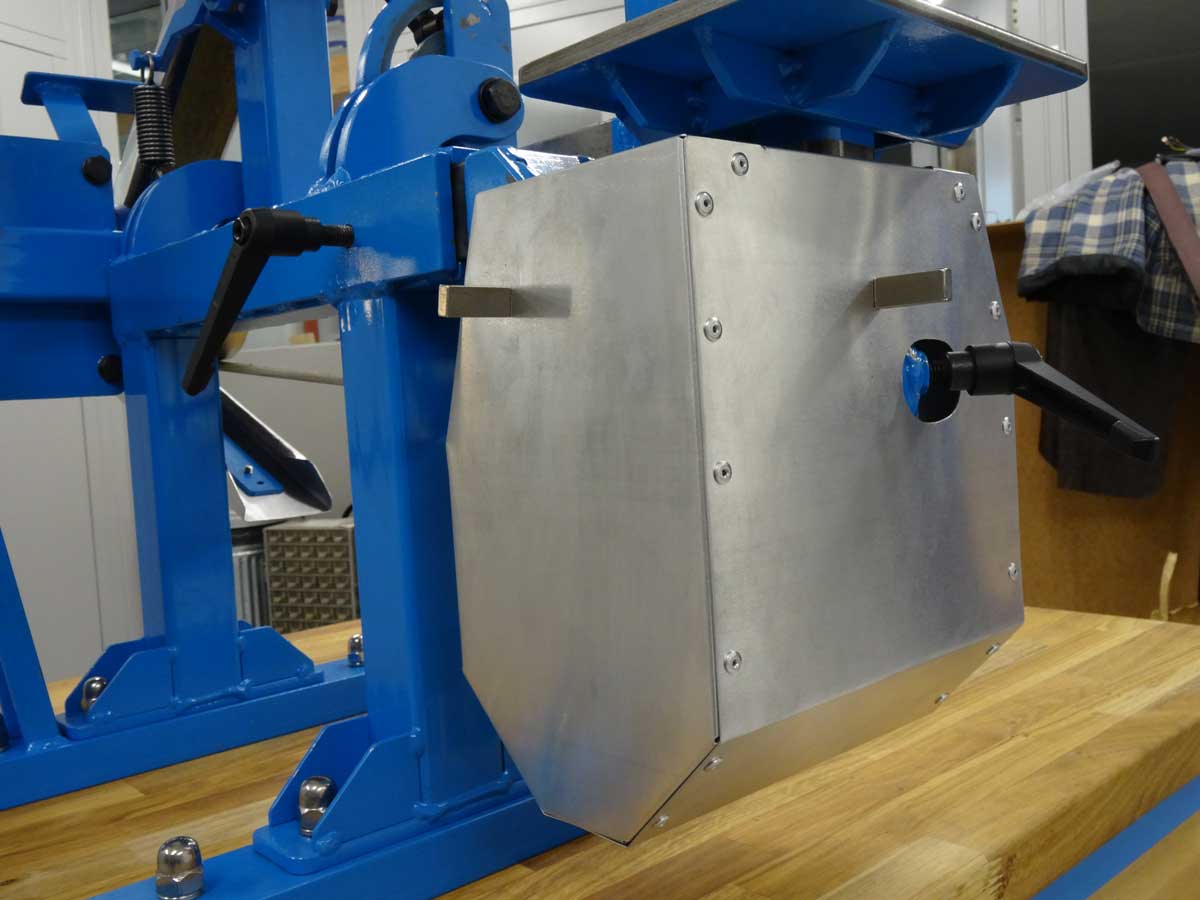

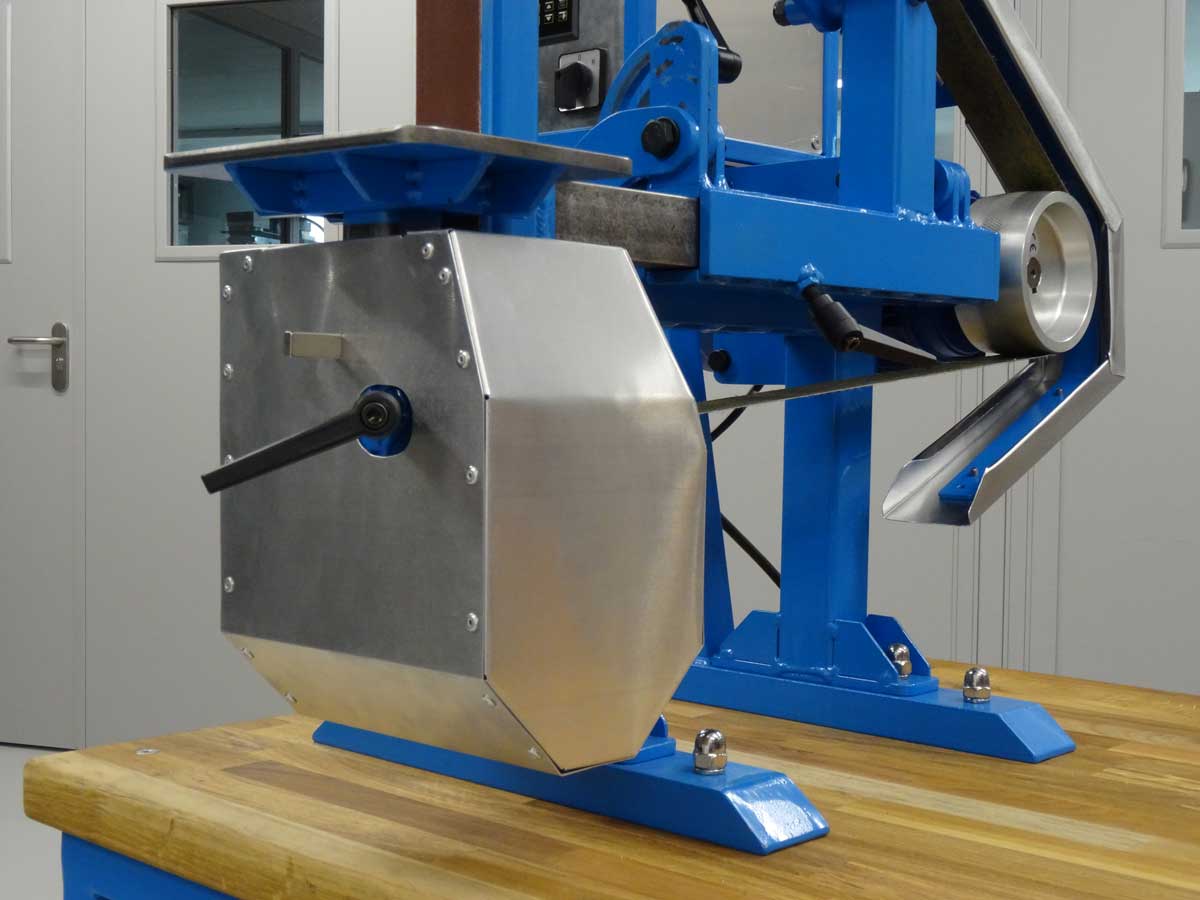

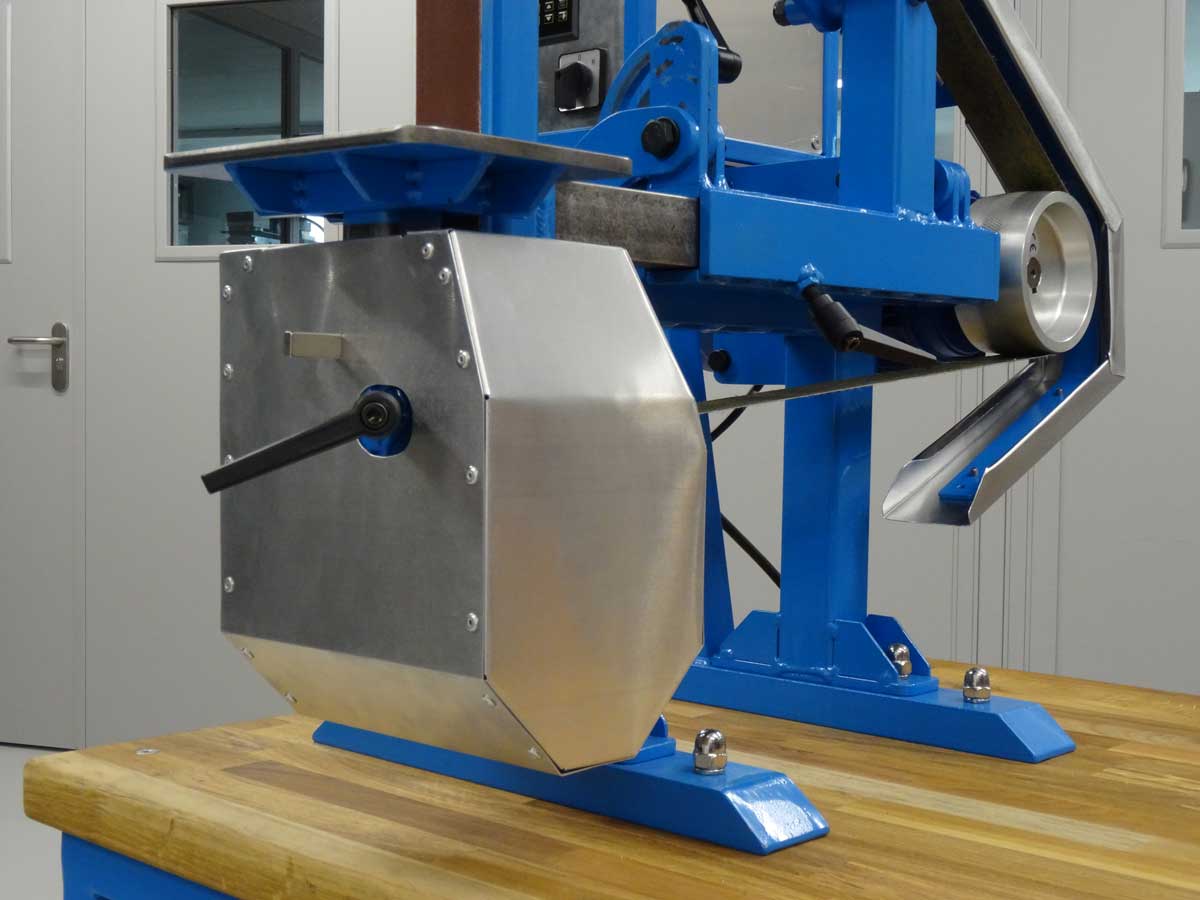

This is what the spark arrester looks like when assembled.

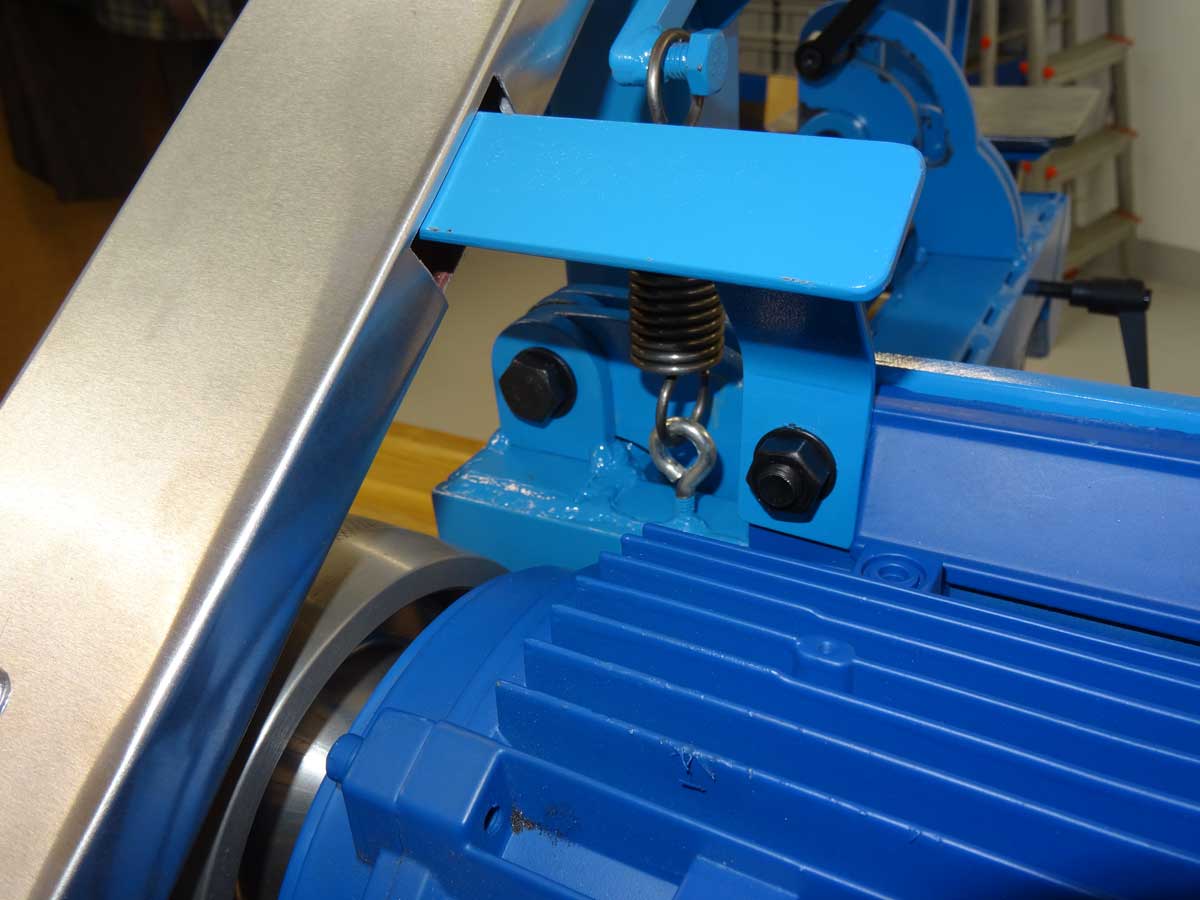

Installation is carried out using one of the 4 screws of the motor mounting.

There are two points to consider when dimensioning: A) Does the spark collector not graze anywhere when I bring the belt grinder into the horizontal position? B) Can I change the belt without any problems (sufficient distance between wheels and sheet metal)?

Now we come to my main spark arrester / dust collector, which can be fitted and removed without tools. In addition to the main function of catching sparks, I had to find a shape that would also allow quick mounting. The cardboard model used for this has proven itself and I was able to find the optimum shape with tests without wasting aluminum sheet unnecessarily.

I always write all the important measurements and notes directly on the cardboard model. I even had to change the colors to keep the overview in this particular case, because I've already made so many changes … I also used 0.8 mm sheet thickness here.

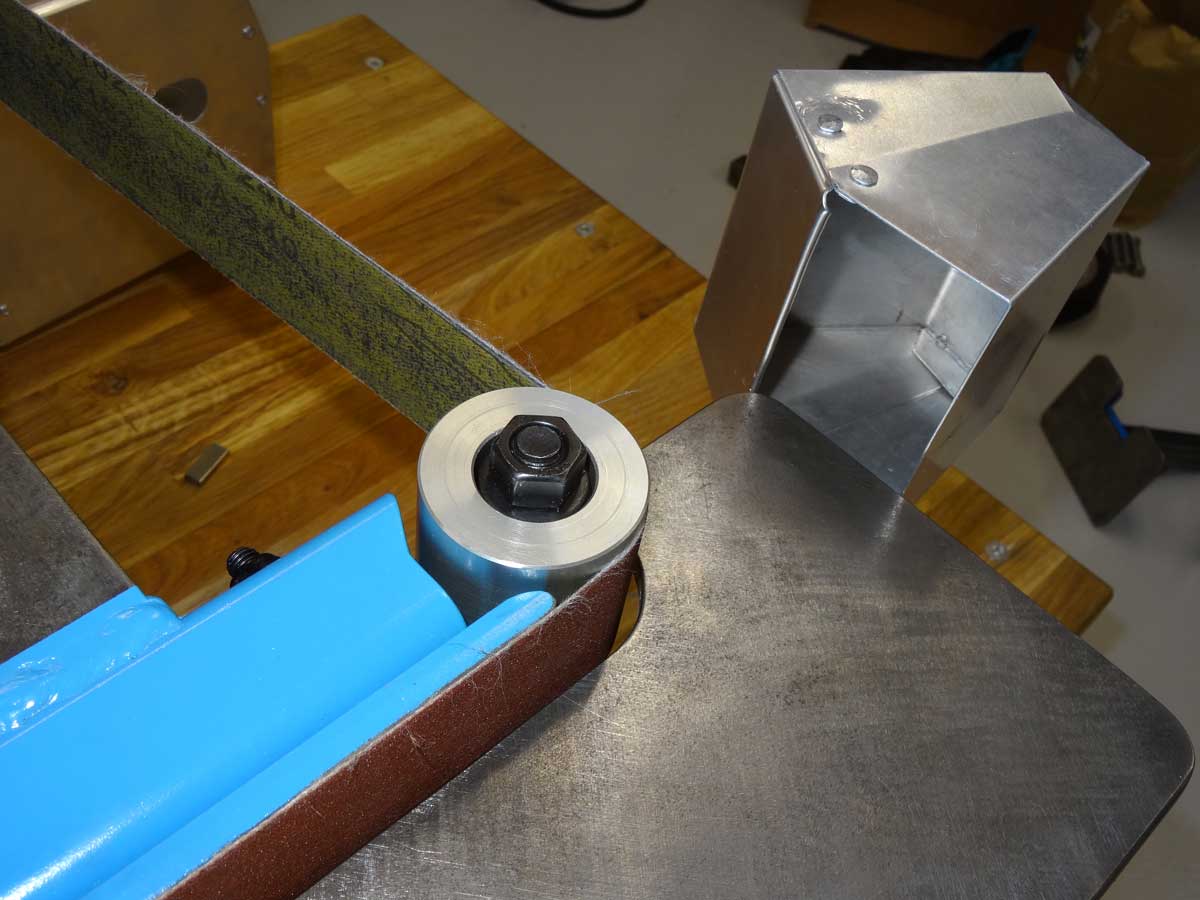

For bending, I clamped an L-profile in the vice and a second clamped the sheet metal in between. You can simply bend the thin sheet by hand.

All 3 sheets are bent and the holes for the pop rivets have already been drilled in the main sheet.

Now I drilled the hole in the side panel on the underside and secured it with a screw. Now more holes follow until every second hole is drilled and secured with a screw. Then the intermediate holes are drilled, everything is dismantled one last time and the holes are deburred.

Now all the pop rivets can be placed and the spark collector is ready.

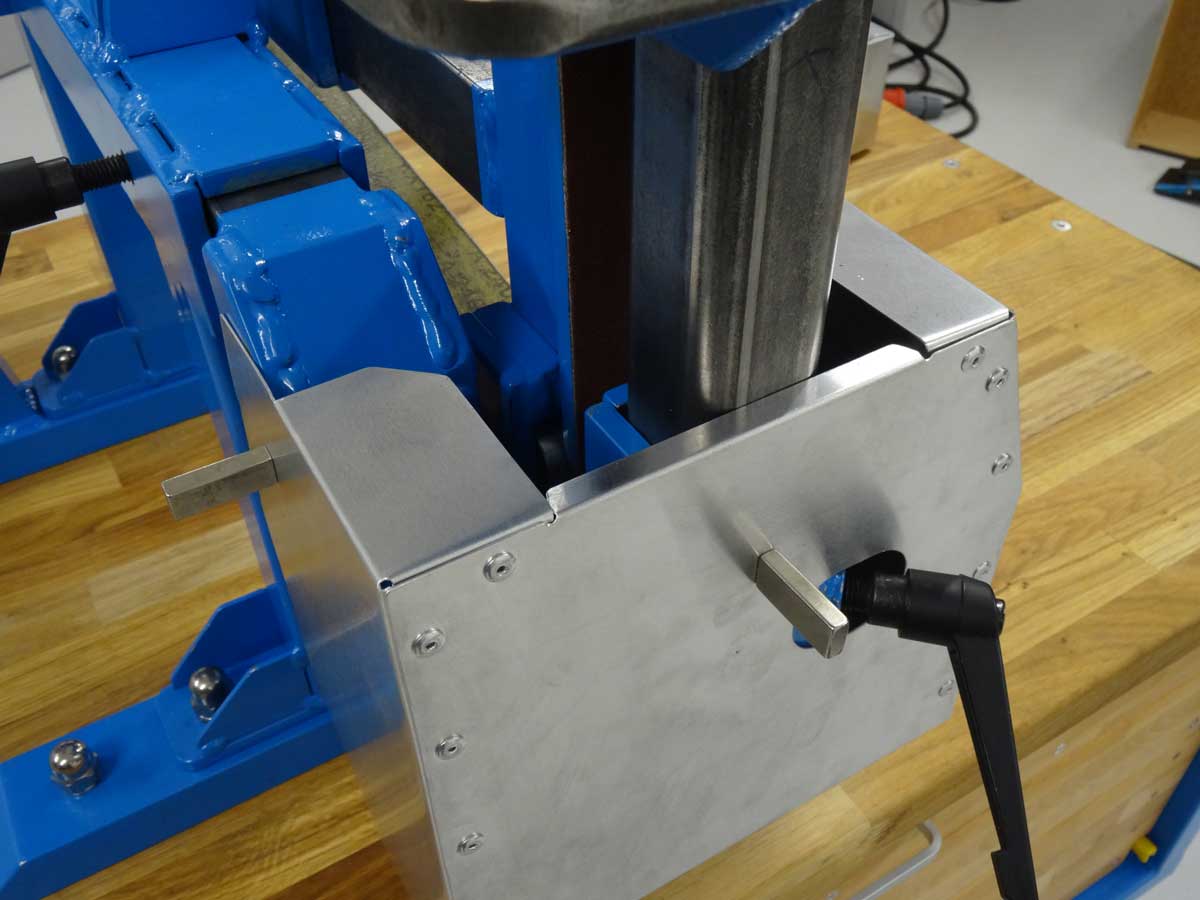

Here is the view from the front with the oval hole through which the handle for adjusting the height of the table is guided.

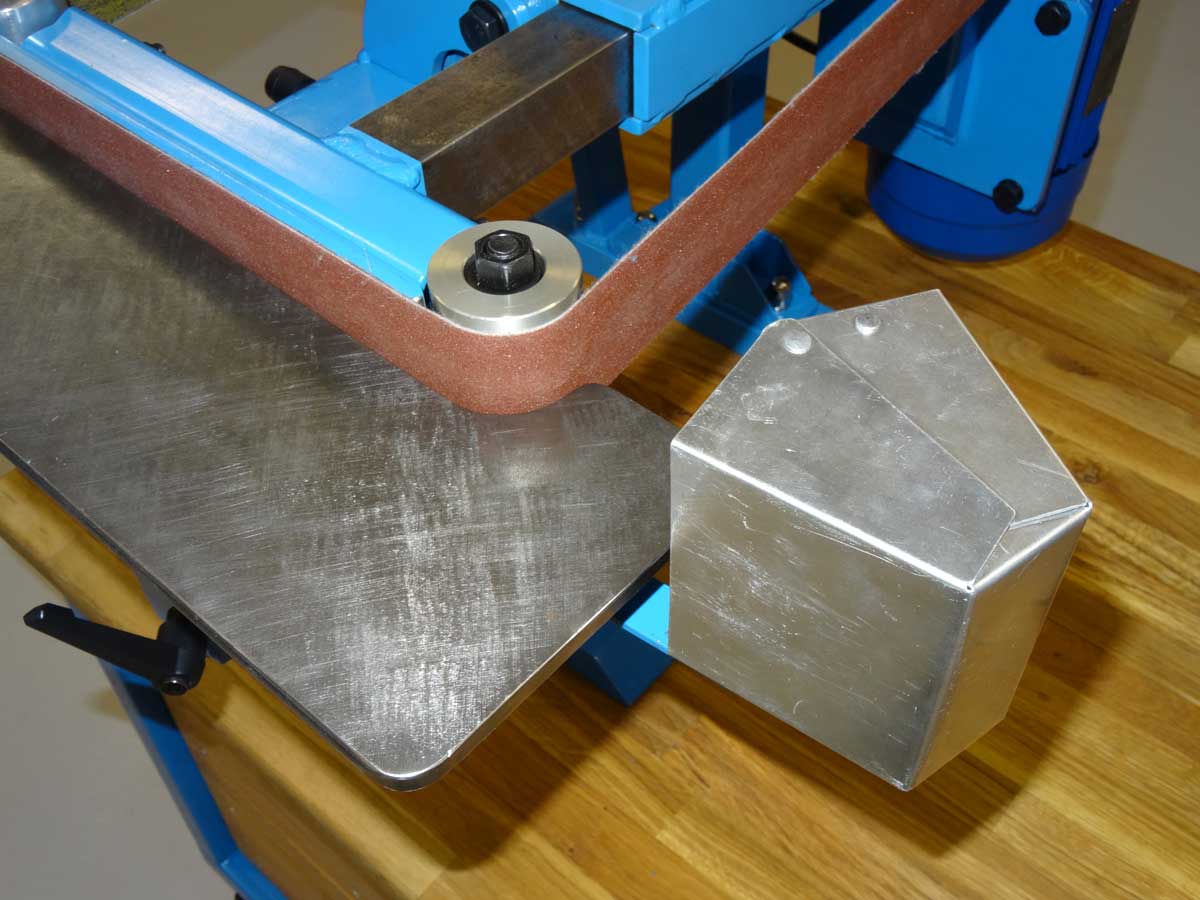

Again for comparison, my cardboard model together with the final spark arrester made of 0.8 mm aluminum sheet.

Now follows the instructions on how to fit the spark collector. 1) First place the lever for the table adjustment in the position shown in the picture (slightly tilted downwards) 2) Guide the spark collector over the lever - the spark collector on the left-hand side is slightly lower than on the right-hand side 3) Push the spark collector further up 4) Move the spark collector completely over the lever and lift the left side slightly so that it is horizontal and rests against the table holder. Done! It takes some practice to get the hang of it, but under no circumstances is force necessary - if it doesn't work, the handle position may be wrong, or you may be trying with the wrong angle of the spark collector.

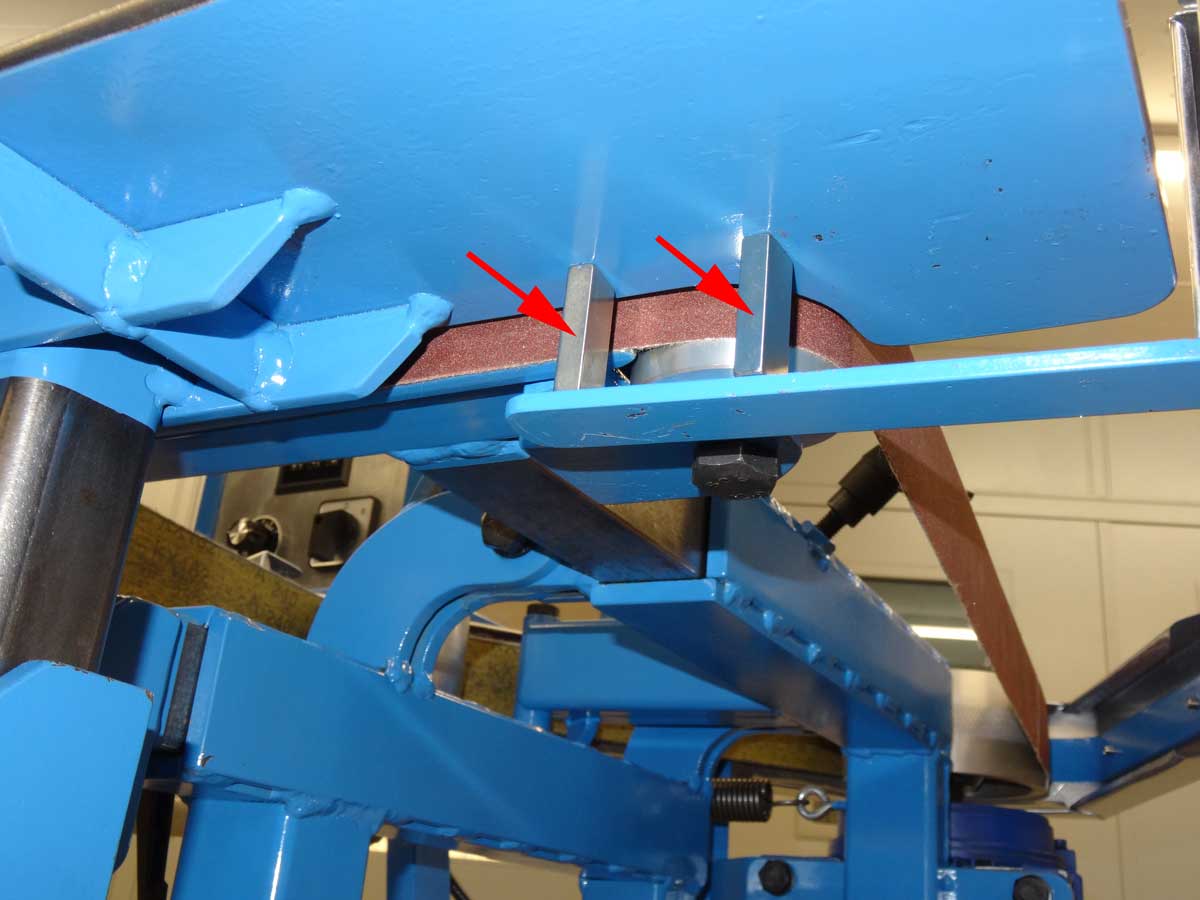

The installation of the spark collector is actually not quite finished yet, because the spark collector has to hold somehow. There is a simple solution for this, simply position 2 super magnets at the 2 positions (see picture) and the whole thing holds.

I have a few comments. The holding force is best when I position the magnets as shown in the picture (north or south pole onto the sheet). Since the aluminum sheet is only 0.8 mm thick, the force of the magnet is only slightly reduced. If someone wants to use thicker material, they should first carry out a test or use a stronger magnet. Be sure to use aluminum, because with a steel sheet the magnet holds on the sheet but there remains not enough force to hold the spark collector on the belt grinder, apart from that it is also heavier than the aluminum version.

Here are a few pictures from different angles.

If you were wondering why the box is slanted on the right-hand side, here is the explanation. The reason is the adjustable angle table, which has the handle for adjusting the inclination on the right-hand side and with this sloping side the handle can easily pass the box.

One of my first tests was with such a small dust Collector. I was able to catch a lot of sparks / dust with it, but it wasn't entirely satisfactory for me. I built this little spark catcher anyway, but I now use it for a different purpose.

Here is example of what can be found in the spark collector after grinding. It is not actually sanding, but cutting. As you can see, the small chips hold together nicely.

It starts with cutting the sheet metal.

I then riveted it in place, adding a cover to half the opening. The idea is that fewer sparks will leave the spark collector.

If you don't need a 100% solution, you can also use this small spark collector instead of the large one. It is also attached with a magnet, which is positioned inside the spark collector.

In this view, you can still see a flat profile attached to the spark collector. It would not be necessary for this purpose, but it does not interfere either. I explain the purpose further below.

The large spark collector is of no use when sanding horizontally. This must be removed before tilting, or at least extend the table sufficiently so that nothing gets in the way when turning the belt by 90 degree …

This is how I now use the small spark collector. First I rivet a flat profile to the box. Then the 2 super magnets are positioned on the flat profile with some distance between them.

Now attach the whole thing to the underside of the table with the magnets.

And this is what it looks like from above.

The exact position can be readjusted as required thanks to the 2 magnets and thus catch most of the sparks when the belt is in horizontal position.

It is a little more difficult with the small wheels, but the small spark collector can also be used here.

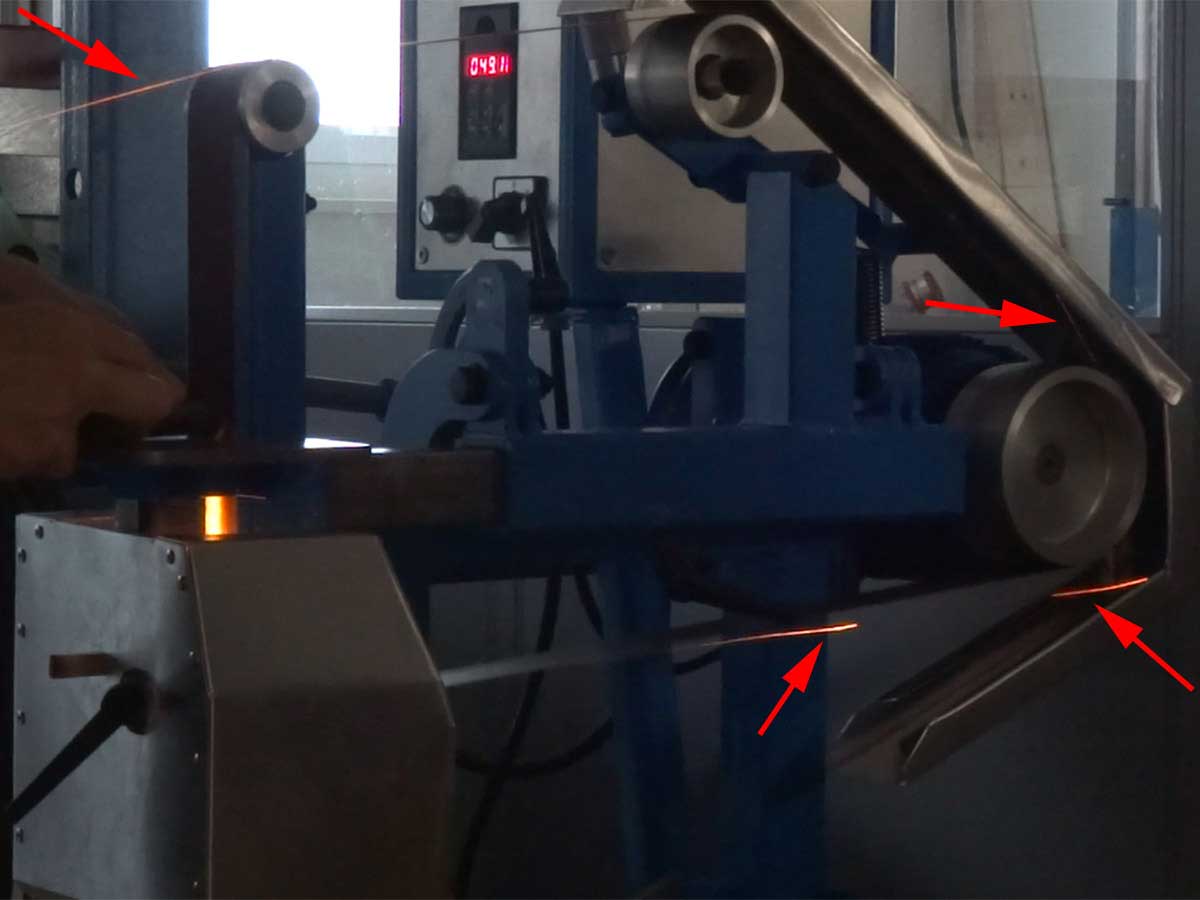

Now that everything has been said about my spark collectors, let's test them with the 72" belt grinder running to see if they work as intended.

The large spark arrester works very well - only a few sporadic sparks are not caught. This also depends very much on how high the table is set.

Now let's take a look at the spark / dust collector. The spark collector works perfectly at the 3 marked positions in the area of the drive wheel. Unfortunately, there are still a few sparks that stick to the belt and thus make a full rotation and then hit me in the chest area when grinding (see marking above). But that's not too bad.

I had an idea by positioning 4 strong magnets 1 mm away from the belt under the drive wheel on the entire belt width to 'suck' the sparks from the belt. Unfortunately, this did not work, as red-hot steel is no longer magnetic above approx. 800 degrees Celsius. In other words, I would have needed a cooling unit beforehand, e.g. in the form of air pressure, but that was a bit too time-consuming for me … ;-)

Next follows

Chapter 6

where I present my mobile table with drawers.

Copyright © 2001-2024 Markus Maurer |

Creation Date: 17.11.2024 |

Last Modified: 17.11.2024