/ford_a/ford_a_restore_2016_08.en.html

To prepare my Model A for longer distances, I had to make some missing parts, which I did last month.

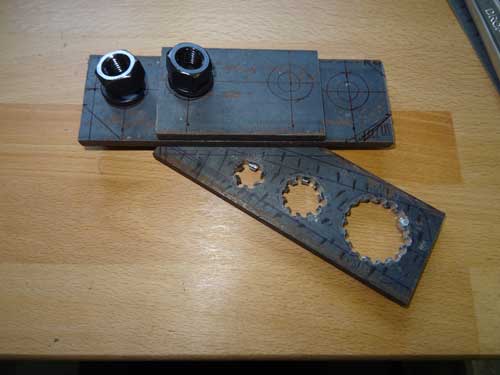

The first point was the missing possibility of being able to tow the car when the engine is not running anymore. One can attach the tow rope to the bumper or the front axle, but I do not want to make more damage on the car. Therefore I wanted to attach a removable hook directly to the frame. In normal operation, no hook should be visible. Here I started with a couple of flat steel profiles.

The three pieces are ready for welding.

On the carrier plate two screws are welded on the back side. The two pieces of the removable hook are also welded together.

This is the view from the front.

With new paint, the parts are ready for installation.

This is how the area of the front frame normally looks …

… and this is the view with my mounted carrier plate.

Now I can loosen the two nuts on the support plate and mount my tow hook.

Everything is ready but I hope that I do not need it …

Since the main part of the car is made of wood, I want to be able to cover it should I'm surprised by a major storm. I have used thin, waterproof nylon, which is light and water resistant. First I have sewn together 4 tracks and laid it over the car.

Now all the fine adjustments for the final cover are made.

The end result, a tailor-made rain cover which fits in this bag.

The bag is put into my trunk.

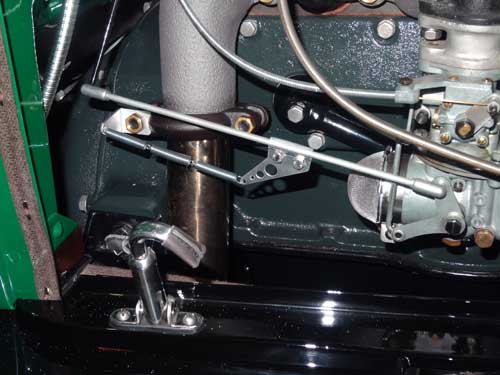

One problem I had with with my carburettor, was a slightly hanging idle. It was not all the time, but very annoying when you have a not synchronized gearbox. The lubrication of the throttle linkage has solved the problem, but after some time, this oil has probably somewhat thickened and the problem was back. For this reason I wanted to pull the throttle linkage back to idle position with an additional spring. Of course, the whole thing should visually look nice and fit in the engine compartment. First I made this spring-holder from a thin sheet of aluminum, which is mounted on the linkage.

The spring-holder is slipped over the rod and can be fixed in the correct position and the spring pressure can be adjusted.

I have mounted a piece of aluminum on the exhaust to connect the other side of the spring. First tests have shown that everything is running as expected and my idle gas is not 'hanging' anymore.

Copyright © 2001-2024 Markus Maurer |

Creation Date: 25.09.2016 |

Last Modified: 05.12.2024